Fangyuan EPS/EPP Moulding Machines

Company Overview

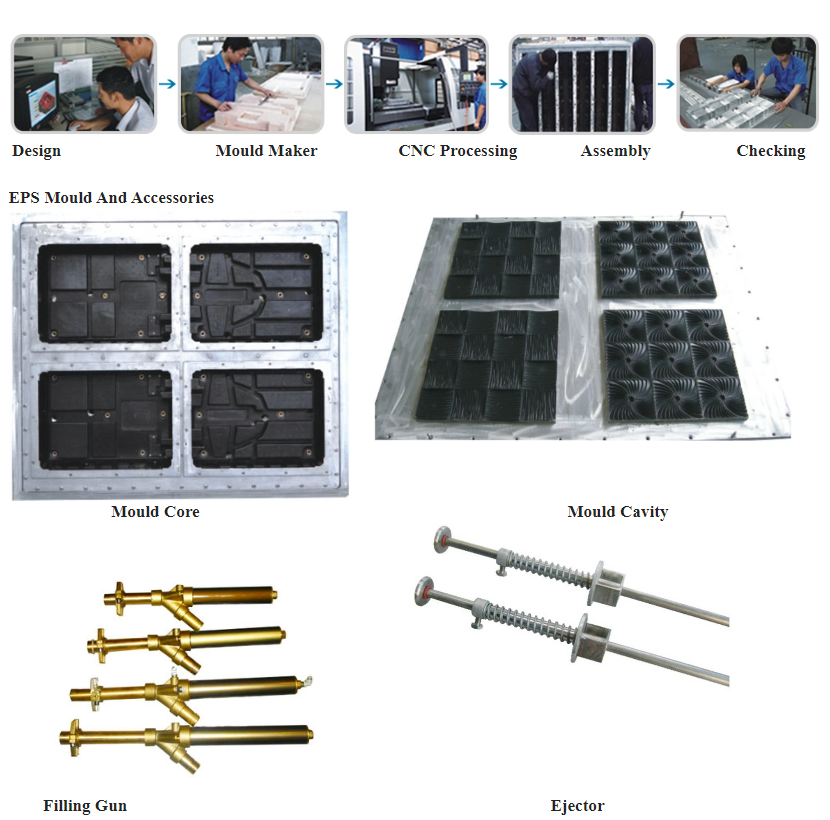

Fangyuan’s Mould Branch is a leader in designing and manufacturing EPS and EPP moulds for various foam moulding applications. Our team, consisting of over 100 skilled professionals—including 20+ engineers and technicians—relies on advanced design and manufacturing technologies, including CAD/UG/PRO E for EPS plastic mould design, CAM programming for precision production, and AutoCAD/2000 for two-dimensional drawings. Our manufacturing process is supported by 10 high-end CNC machining centers and nearly 30 general mould machining tools, ensuring the creation of high-performance EPS moulding machines.

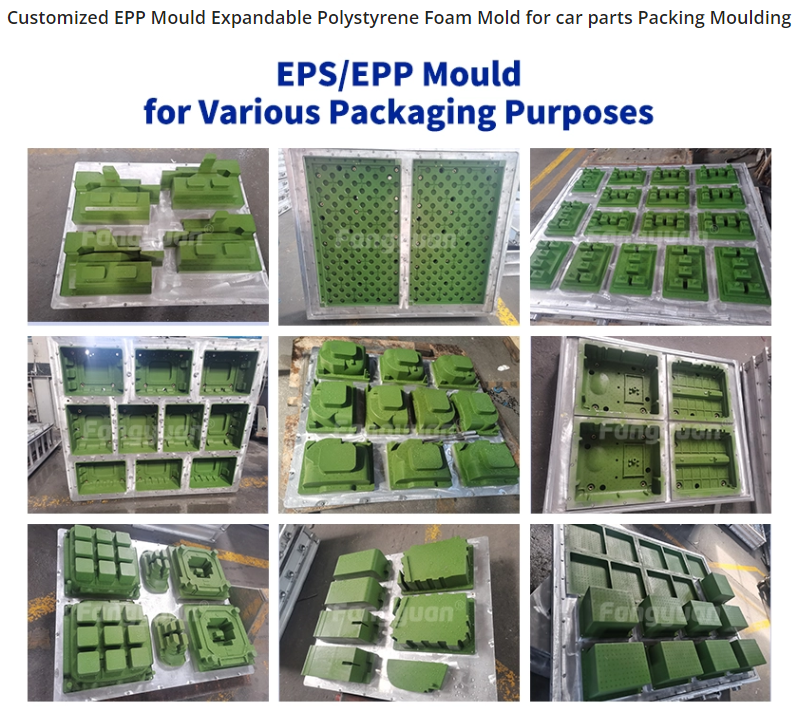

We specialize in producing EPS, EPP, and thermocol moulds tailored to meet the diverse needs of industries that require foam moulding solutions. Our 6063 high-quality aluminum alloy moulds are known for their superior durability and precision, guaranteeing high-quality results over long-term use.

Key Features of Fangyuan EPS Moulds

-

High-Quality Aluminum Alloy Construction

Fangyuan’s EPS moulds are made from 6063 aluminum alloy, a material known for its strength, durability, and resistance to wear. This ensures that our moulds offer long-lasting performance, even under continuous production conditions. -

Advanced Design and Manufacturing Technology

Using CAD/UG/PRO E for design, and CAM programming for precision manufacturing, our moulds are crafted to meet the highest standards. We ensure each mould is built with careful attention to detail, ensuring reliable and consistent results in every production cycle. -

Standard Mould Chambers and Cooling Systems

Fangyuan’s moulds come with standard mould chambers and cooling systems, optimized for uniform cooling and efficient operation. This reduces cycle times and enhances the overall production speed while maintaining high-quality output. -

Teflon Coating for Superior Performance

The surface of our EPS moulds is treated with a protective Teflon coating. This coating provides excellent lubrication, prevents material from sticking to the mould, and makes de-moulding easier and faster. Additionally, it reduces maintenance and enhances mould longevity. -

High-Temperature and Corrosion Resistance

Designed to withstand temperatures above 350℃, Fangyuan’s EPS moulds offer excellent resistance to high heat and corrosion. These features make them ideal for applications requiring high-temperature processing, extending the mould's service life and ensuring consistent performance over time. -

Durable and Long-Lasting

Our moulds are built to endure the rigours of high-volume production. The 6063 aluminum alloy construction, combined with the Teflon coating, ensures long-lasting durability and consistent results across many production cycles, helping you maximize your return on investment. -

Versatile Applications

Fangyuan’s EPS and EPP moulds are designed for a wide range of applications, including styrofoam packaging, foam boxes, and other custom shapes. Whether you need standard or retractable moulds for thermocol or EPP, we provide tailored solutions to meet your specific requirements. -

Efficient Production and Easy Maintenance

The design of our moulds ensures efficient production with minimal downtime. The easy-to-demould feature, along with low-maintenance requirements, helps improve your overall production efficiency while keeping operational costs down.

Conclusion

Fangyuan’s EPS/EPP moulding machines represent the perfect combination of advanced design, high-quality materials, and cutting-edge technology. Built from 6063 aluminum alloy and featuring Teflon coatings, these moulds offer durability, high performance, and resistance to extreme temperatures. Whether you are producing styrofoam packaging, EPS foam boxes, or other foam products, Fangyuan delivers customizable, reliable moulding solutions that ensure high-quality results, long-lasting performance, and optimal efficiency.

Contact us today to learn more about how Fangyuan’s EPS moulds can help enhance your production processes with precise, durable, and efficient solutions.

QQ

QQ